✅Testing is a common way of assessing the behavior of a structure, that can be used for direct characterization, structural dynamics modifications using modal models, or for correlation and model udpating. When using intrusive sensors, the effect of their presence also needs to be assessed. Accelerometers are widely used in the industry due to their good cost compromise regarding cost and usage flexibility. In this post we will focus on the added mass effect coming with their positioning, dealing with the two following points:

👉How to assess accelerometer added mass effect to a tested structure?

👉What are the implications on the observation, especially when doing batch measurements?

⚠️ The added mass of accelerometers (and their adapters and cables) has to be evaluated with respect to the tested structure mass. Dealing with lightweight components, that may feature many modes in the frequency range of interest, becomes more and more common due to the extensive use of aluminum, composites, and topological optimization. Sensor placement thus has to be performed with care as discussed in one of our other posts https://www.sdtools.com/test-campaign-design-using-a-model/.

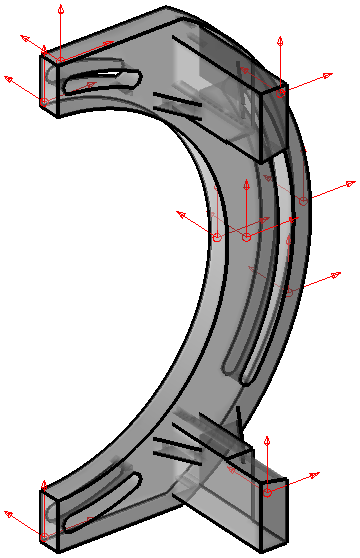

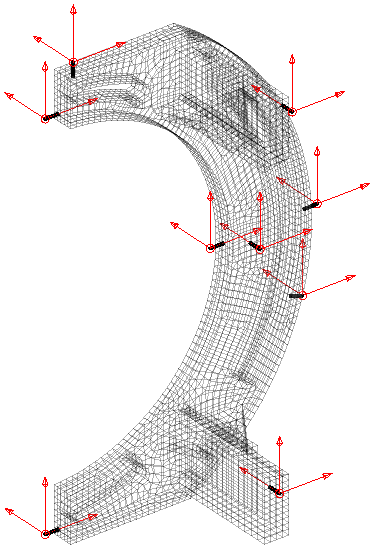

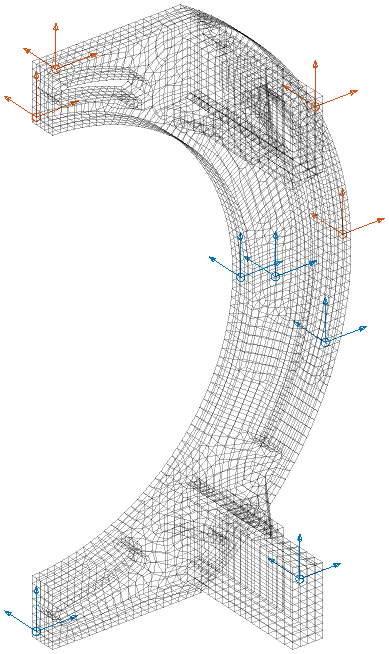

🎯 Our working example is a bracket component we call the banana bracket, designed to be representative of an automotive component. It is made of steel and weighs 5.12 kg. To be able to observe properly all its flexible modes under 6kHz, 9 triax accelerometers are necessary. The chosen position ensures a clean AutoMAC matrix, and the associated fixed sensor modes are close to 2kHz, which gives a good confidence in the ability to observe any low frequency mode in the case where the model was significantly offset.

To ensure a proper assessment, the accelerometers are modeled as punctual masses whose localization is offset by half the height of typical accelerometers (1cm is common).

Depending on the accelerometer, the mass can vary from a few grams for very light sensors to over 100 grams. Considering that we are adding 9 of them, the total added mass can vary from 0.2% to more than 20% of the banana bracket mass!

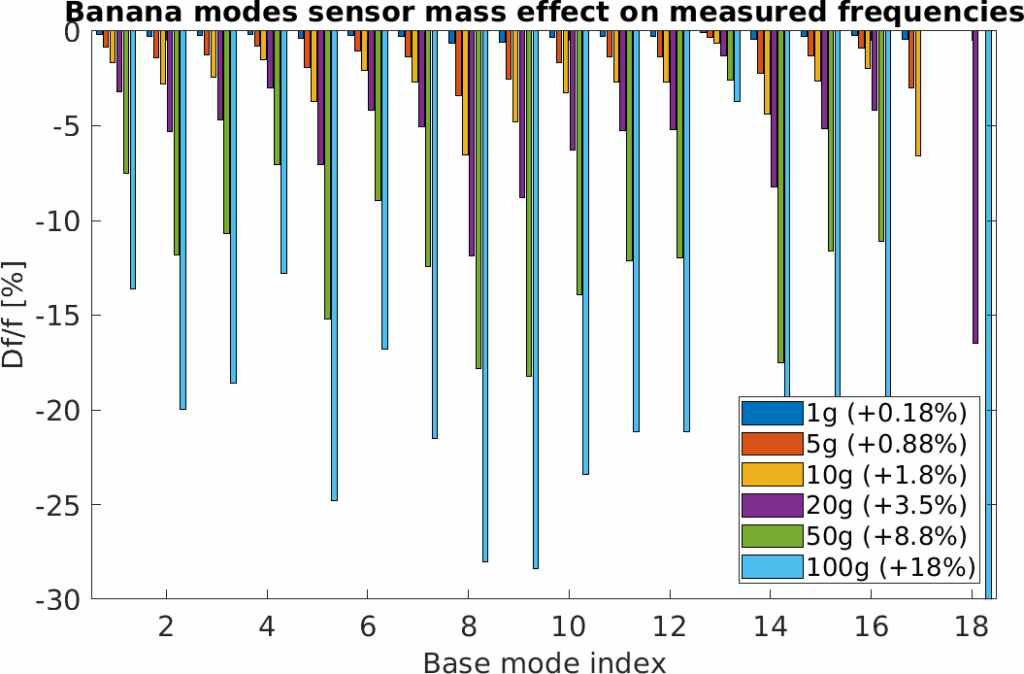

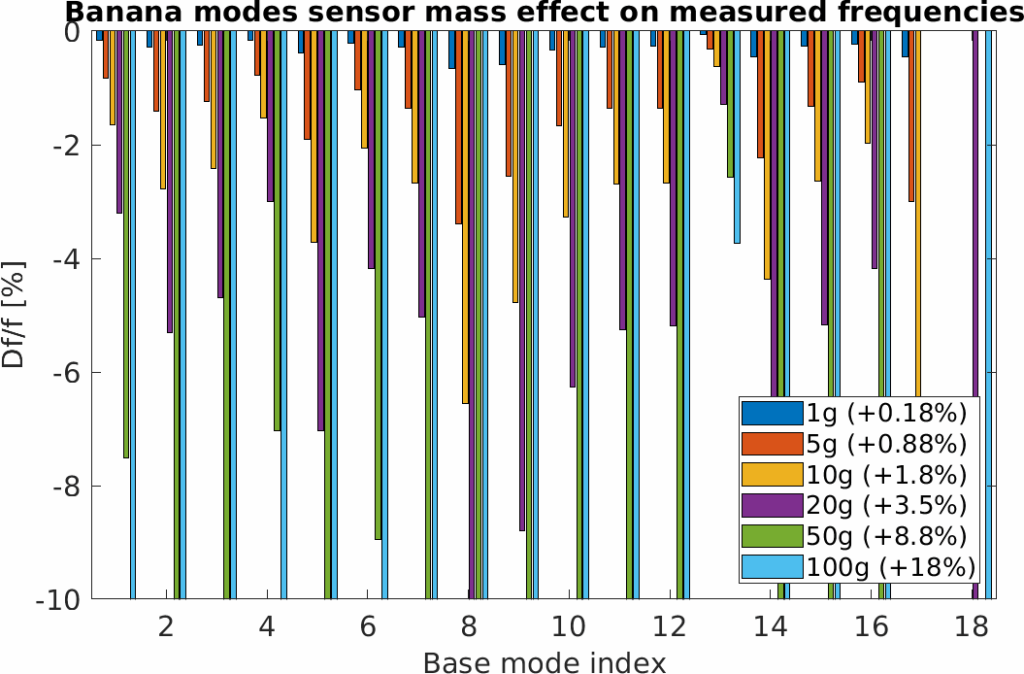

The effect on frequencies is not negligible. For the light 1 gram sensors, a maximum of 1% in frequency deviation is observed, already attaining more than 3% with the 5 grams configuration. Getting to the ‘heavier’ options, deviations of 15% or more are expected.

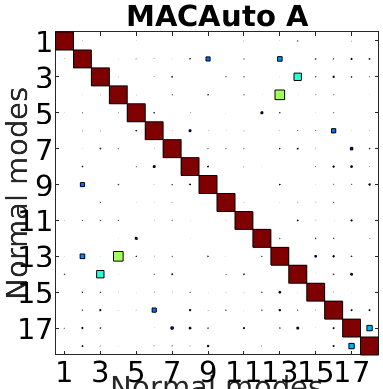

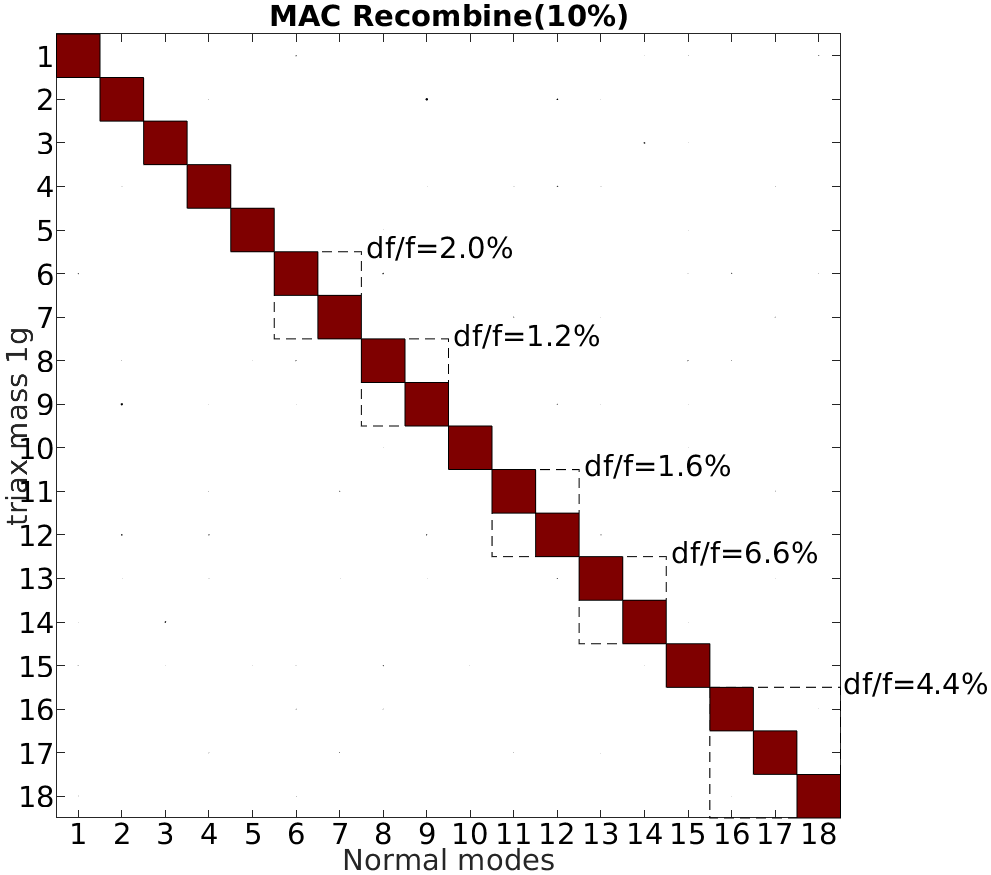

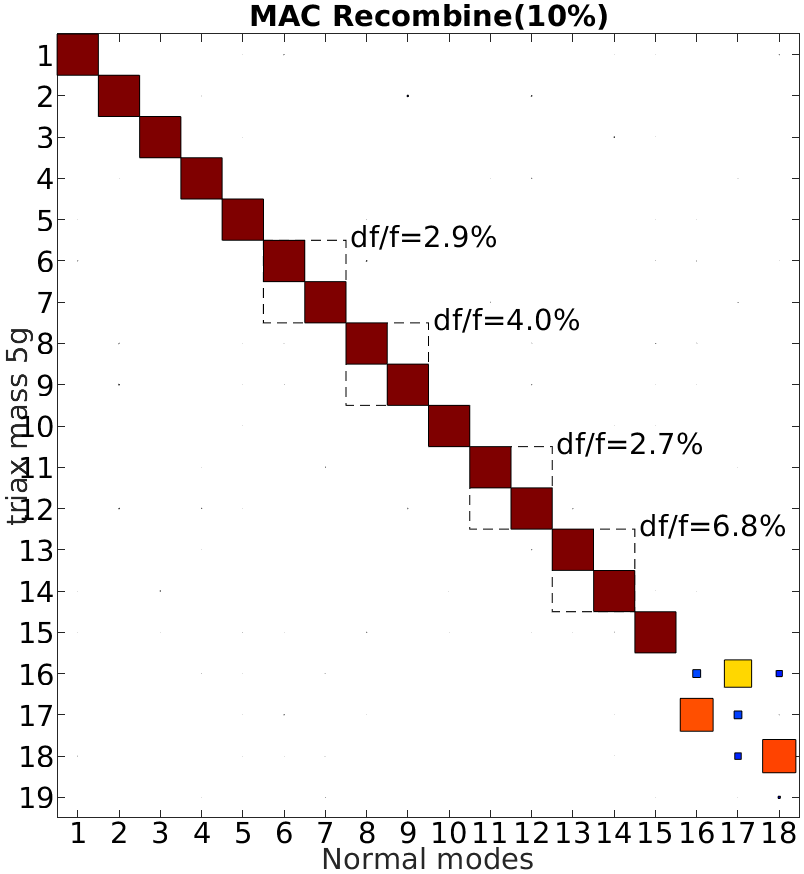

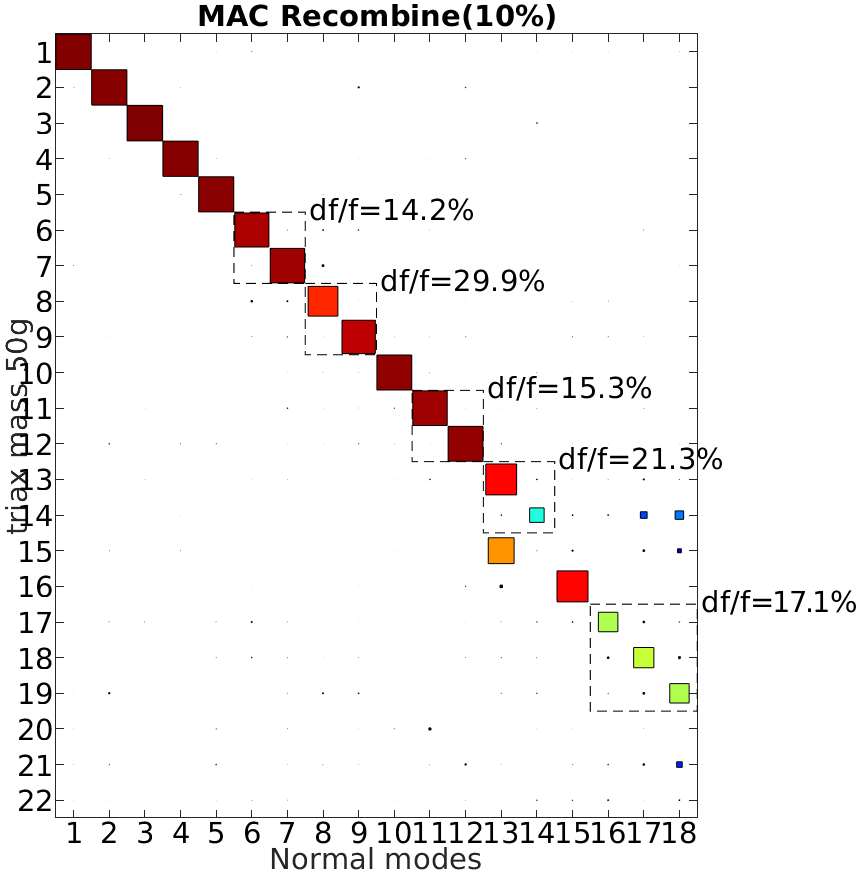

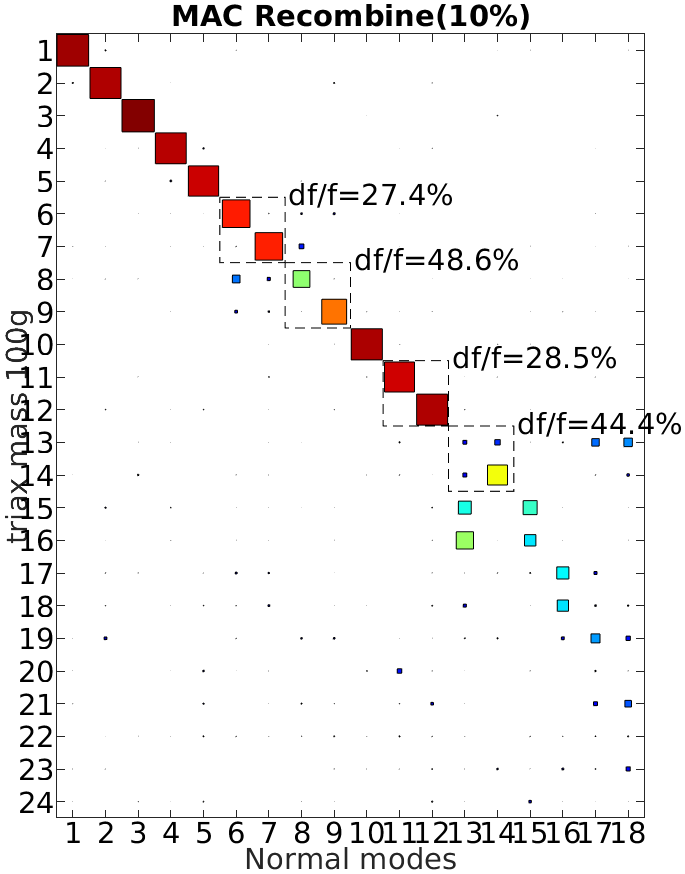

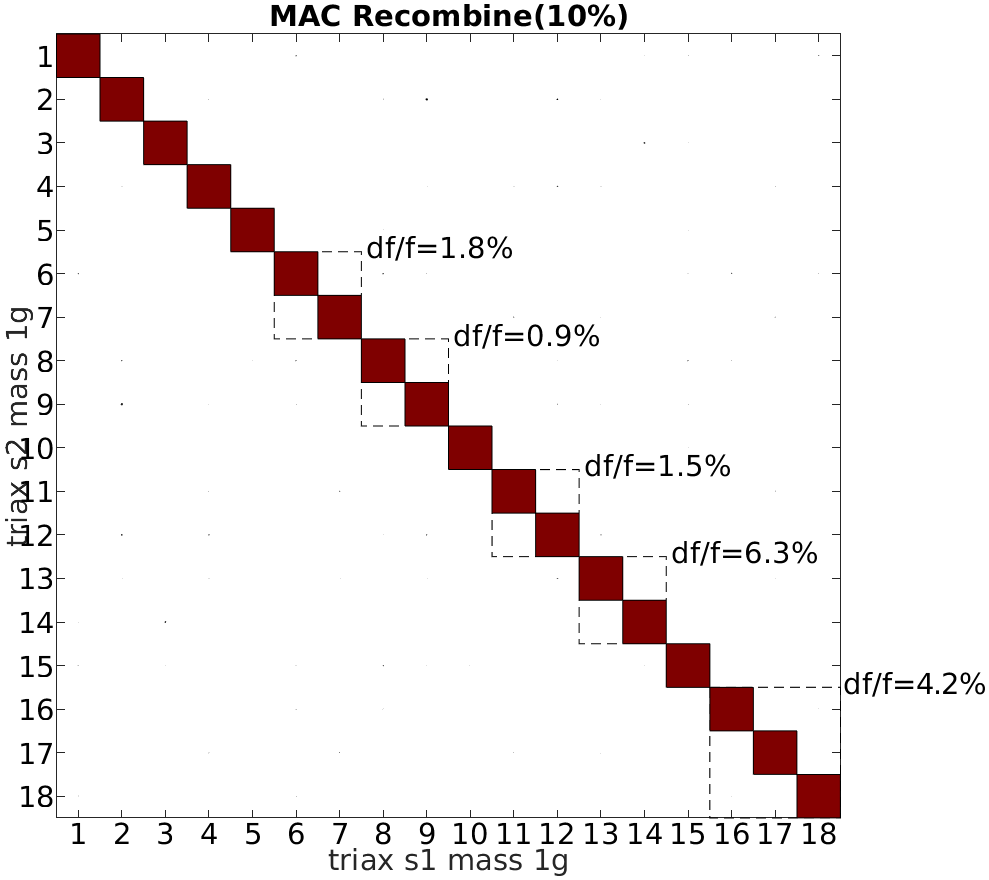

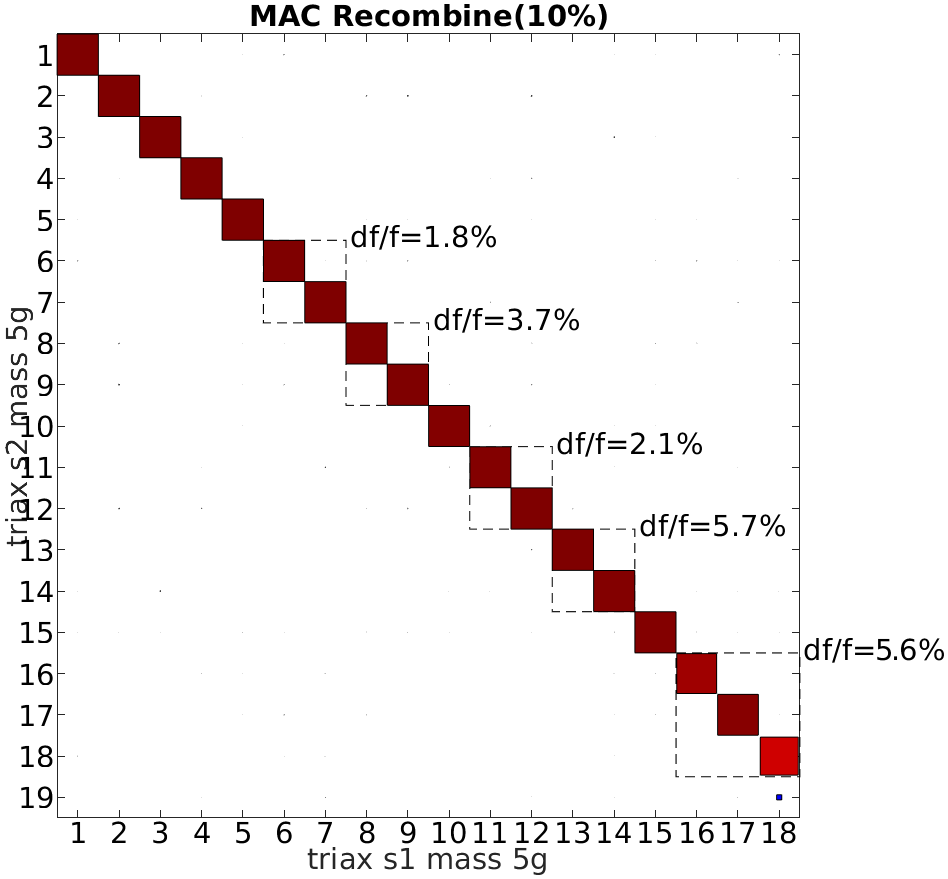

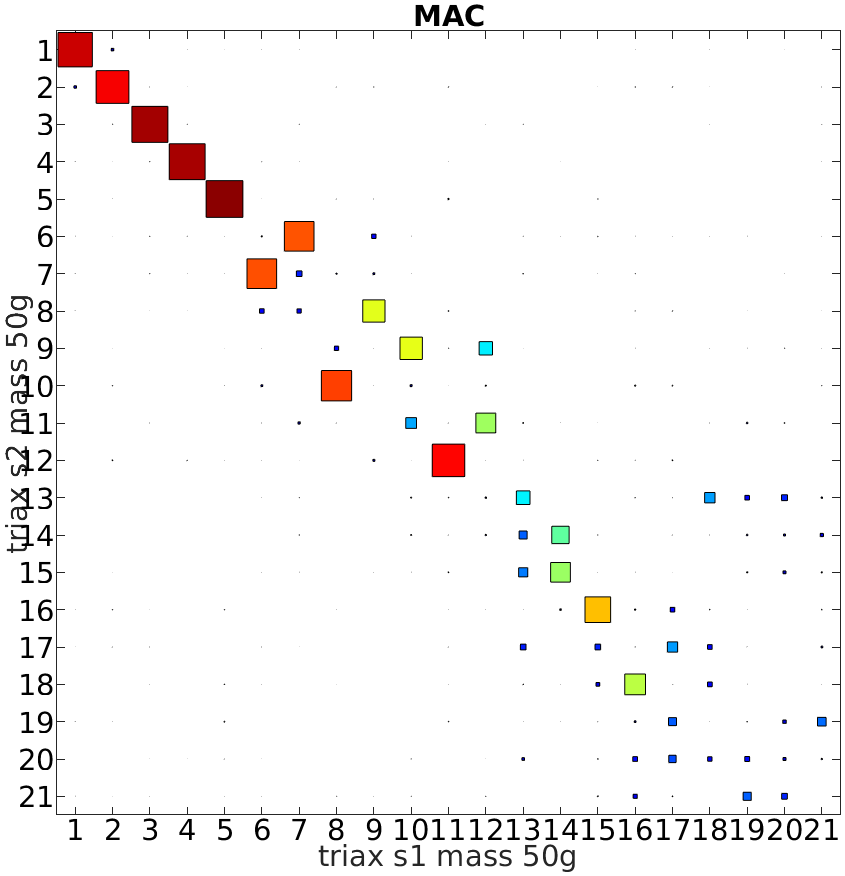

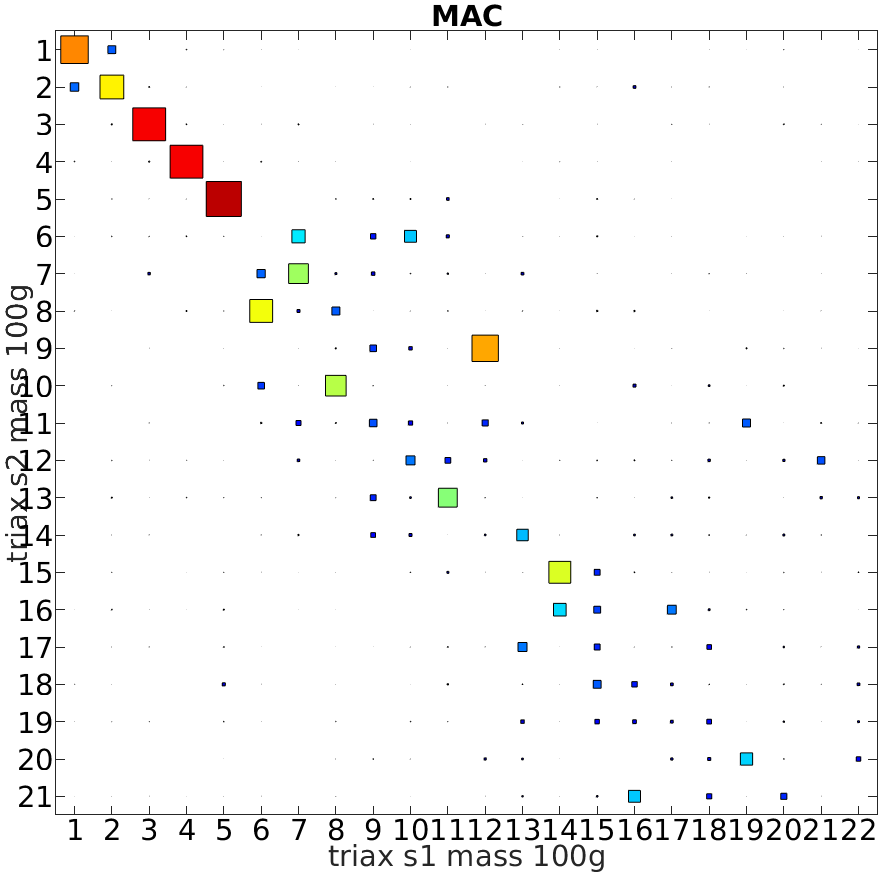

Besides frequency the shapes can also be altered, the MAC between the base modes and the added sensors configurations are presented below. Our MAC recombination feature is enabled to ensure robustness to mode crossing related to the quasi-double modes associated with the banana columns bending. The higher frequency modes around 5kHz are impacted even with 5 grams sensors. Getting to 50 grams and more, the higher frequency content becomes very different.

The observation of the added mass configuration modeshapes illustrate the phenomenon. For the lower modes, the global shape does not change, but getting to modes where the displacement can become more localized the sensors position can alter the displacement field or even generate new modes in the frequency bandwidth as mode 16 with the local banana foot torsion.

When more sensors are needed than the available volume in the lab, either by a limited supply of accelerometers, or of acquisition channels, measurements can be performed by batch. Several runs are then performed using different sets of locations for each. It is then necessary to glue dead masses of equivalent weight at measurement positions where no sensor is placed in the current batch. Otherwise, measured modeshapes can deviate between batches and the merger will be impossible without numerical treatment.

In our example, assuming that up to fifteen channels are available, two sets of triax sensors are generated whose position in blue and red is presented below: Note that it is necessary to keep at least one common sensor for all batches to enable merging. The common sensors will work as a reference and allow calibrating amplitude and phase between batches.

Comparing the modeshapes with the MAC directly shows the challenge ahead if no dead mass is added at non measured positions. From the 5 grams sensor a new mode appears on only one set. For higher mass configurations, passed the first few modes, the modeshapes become clearly different so that both batches cannot be considered as measuring the same structure.

Other aspects of sensor setup will also be discussed in future posts. In particular, performing correlation with batches showing deviations using modal expansion will be a subject of its own.